Success Story

HOME / SOLUTIONS / SUCCESS STORY

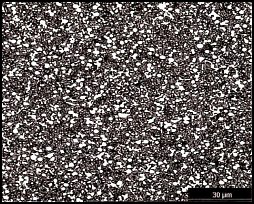

Check Hardness of Carbides

M/s. Precision Machinery was trying to find out a process to check the hardness of the carbides they have purchased as coating material. They also wanted to check the harness profile of the coated component. They were looking for a solution for the above critical test, so they used to send the samples to external labs, but most of the time these testing labs refuse to take test. They were looking out for a practical solution for their application. The main critical issue of this problem was that, the components are extremely hard and hence very difficult to prepare the sample to carry out hardness test. Also effectively performing a hardness test on a single carbide particle was a challenge.

What happened Next?

Client approached us, with the requirement. Technosys developed a process in their application center in Pune, how to prepare the sample for the test. Also automated hardness profile testing on components and carbide particles are established. Tests were carried out successfully with simple procedure. This gave us opportunity to establish a turnkey project to setup a material testing lab Precision Machinery LLC mainly targeting Laser Cladding, Thermal / Plasma Spray Coating and specialized coating. Facilities Provided: Sample Preparation Equipment set (Metkon), Automatic Image Analysis System with Optical Microscope (Clemex), Automatic Micro Hardness Tester (Clemex), Universal Hardness Tester (Affri). Most importantly Procedures / SOP developed for entire process, training imparted to the operators for optimal use and produce reliable and accurate results.

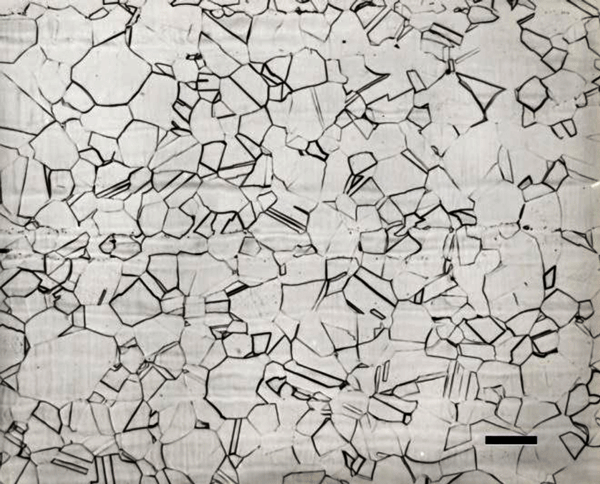

Grain Size Analysis of Alloy Steel

One of our prestigious customer supplies Gears and Automotive parts to German leader ZF, had a challenge in measuring Grain Size in the special industry standard ZFN 5016. First of all it was very difficult to etch sample to reveal the grains. Our technical team could develop a simple process to etch the samples properly to reveal the austenitic grains properly. Later developed a customized routine in the Clemex Vision PE Image Analysis system for automatic measurement of grain size in ZFN 5016 standard and generate report with Pass Fail criteria.

Our Main Strength

- Knowledge on the instruments and applications.

- State-of-the-art Instruments and equipments

- Smart, Experienced, and Hard working Engineers.

- Imparting the training to customer for efficient use of the equipments.

- Providing Quality and Professional solutions